17

17

In the biotech industry, maintaining enzyme integrity is paramount to ensure the production of high-quality products. Contamination by RNases, enzymes that degrade RNA, poses a significant threat to production processes, compromising the quality of final products and leading to costly production errors. As a result, monitoring for RNase contamination has become an essential component of enzyme quality control.

One of the most reliable tools for this task is fluorescence-based RNase assays, which provide a streamlined approach for detecting contamination, ensuring high accuracy and reliability in fast-paced production environments.

RNase contamination can disrupt critical workflows in biotechnology production, particularly when RNA plays a pivotal role, such as in the production of mRNA vaccines, RNA sequencing, and gene therapy. Even trace amounts of RNase can lead to degradation of RNA, affecting yield, quality, and function. This contamination not only compromises the product but can also cause delays in production, costly errors, and in extreme cases, lead to product recalls. Routine RNase detection is vital in minimizing these risks, ensuring that production teams can consistently meet quality standards.

By incorporating regular RNase testing into their protocols, production teams can proactively safeguard their workflows. Detecting RNase contamination early prevents downstream issues, ensures higher quality, and protects against loss of valuable resources. Therefore, integrating RNase detection into the quality control processes is a crucial step for maintaining production integrity.

Fluorescence-based RNase assays have emerged as a preferred method for detecting RNase contamination. These assays utilize fluorescent probes that bind to RNA substrates. When RNase is present, it degrades the RNA, releasing the fluorescent signal that can be easily detected. This method is particularly advantageous because it is sensitive, reliable, and faster than traditional RNase detection techniques.

In high-throughput production environments, where time is critical, fluorescence-based assays offer rapid and accurate results. Their high sensitivity ensures that even minimal RNase contamination is detected early, preventing production disruptions. Additionally, these assays can be easily integrated into automated workflows, enhancing the overall efficiency of quality control procedures.

To successfully integrate fluorescence-based RNase assays into production workflows, it is essential to follow a few best practices. First, establishing standardized procedures for assay setup, sample handling, and data interpretation is crucial. These standardized procedures ensure consistency across batches and reduce the risk of human error.

Proper sample handling is another important consideration. Contaminants from the environment, such as skin or dust, can introduce RNases into the assay, skewing results. Implementing strict sample handling protocols and using RNase-free materials will help minimize this risk. Finally, production teams should undergo regular training to ensure they are proficient in preparing and running the assays, which leads to more reliable data and efficient quality control.

Maintaining the accuracy and reliability of fluorescence-based RNase assays requires ongoing monitoring and maintenance. Regular equipment calibration is essential to ensure that assay readings remain precise. Instruments used for fluorescence detection, such as plate readers, should be calibrated periodically to avoid drift in measurements.

Assay performance should also be monitored over time by running controls alongside production samples. These controls help identify any potential issues with the assay reagents or equipment before they affect the production process. Additionally, troubleshooting common issues—such as low fluorescence signals or high background noise—can prevent false negatives or positives, ensuring that the assay delivers accurate results every time.

One of the key advantages of fluorescence-based RNase assays is their ability to streamline the quality control process. By reducing assay time and minimizing errors, these assays contribute to faster batch releases, allowing production teams to meet deadlines more effectively. Furthermore, the assays’ automation compatibility enables production teams to process multiple samples simultaneously, reducing the overall time spent on quality control.

Incorporating these efficiencies into daily workflows not only boosts productivity but also reduces the risk of costly production delays. Production teams can further enhance efficiency by conducting regular training sessions, ensuring that all team members are proficient in the assay process and can troubleshoot issues quickly.

In a real-world example, a biotech production facility implemented fluorescence-based RNase assays into their quality control workflow. The company, previously reliant on older detection methods, was experiencing delays due to false positives and lengthy assay times. By transitioning to fluorescence-based assays, they reduced assay times by 30%, minimized contamination risks, and improved overall product quality. This shift not only increased their output but also reduced production costs, enabling the company to meet tighter deadlines and expand their operations.

Conclusion

Fluorescence-based RNase assays are a critical tool for ensuring enzyme quality control in biotech production. By detecting RNase contamination early, these assays help maintain high-quality enzyme output, reduce production downtime, and improve operational efficiency. To maximize these benefits, production teams should continue to refine their workflows, incorporating best practices for assay implementation, monitoring, and maintenance. Ultimately, ongoing assessment and optimization of production processes will contribute to long-term success in the biotech industry.

Hzymes has designed and developed RNase detection kit based on nucleic acid fluorescence substrate method.

After special sequence design, the probe can identify a variety of RNase respectively, and meet the detection needs of a variety of samples in a variety of scenarios. Compared with an imported brand (fluorescent probe method), the minimum detection limits of RNase detection kits were as low as 1/8.

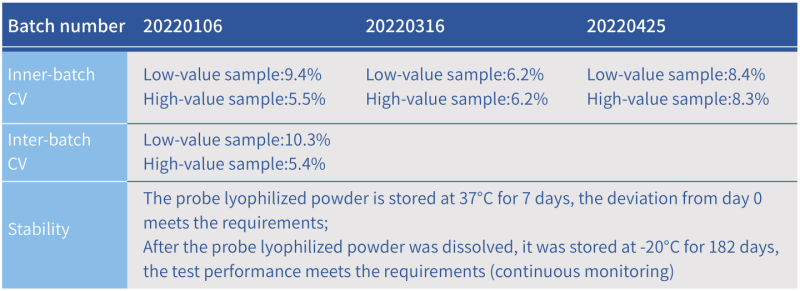

At the same time, the kit has gone through complete methodological verification, and the quality control is guaranteed. To test buffers or materials commonly used in molecular experiments, Hzymes Kit interferes with fewer species. For some samples with interfering substances, it can be diluted with water and tested according to the actual use scenario

Characteristics of Products

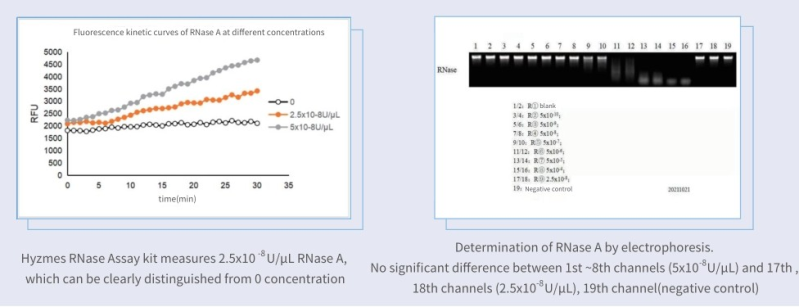

Sensitivity higher than gel electrophoresis method

The Hzymes RNase Assay kit was in comparison with the nucleic acid hydrolysis-gel electrophoresis method, the same low-concentration enzyme samples were measured as shown in the figure below.

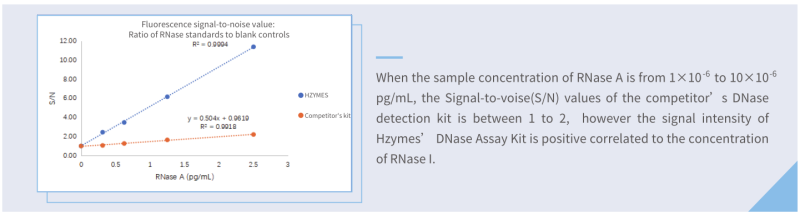

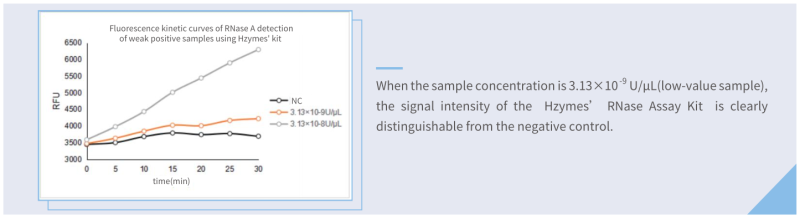

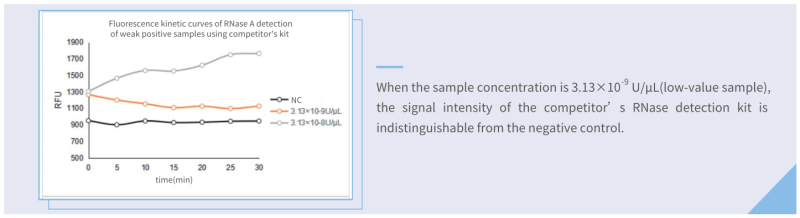

Sensitivity: Hzymes RNase Assay kit VS competitor kit

Compared with one of the best competitor kits (fluorescence), the limit of detection of Hzymes RNase Assay kit is only 1/8 of that of the competitor kit.

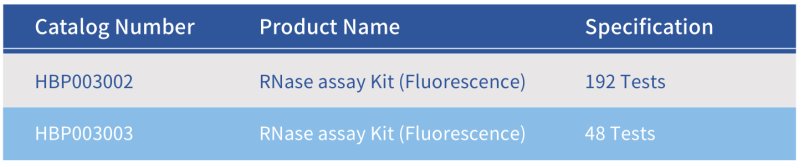

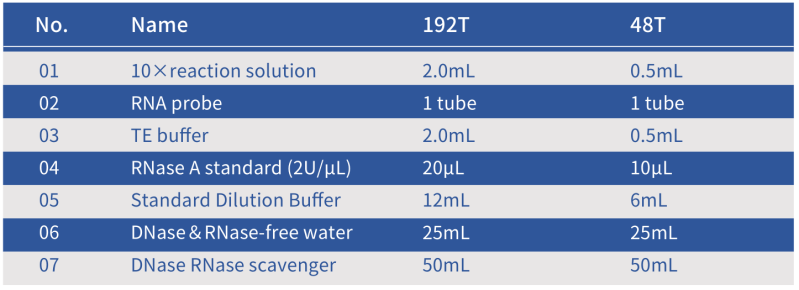

Composition of the Hzymes RNase Assay Kit

Note: The standard is RNase A. The unit for RNase A activity is defined as the amount of enzyme that increases 1.0 in the absorbance at 260 nm of yeast RNA at pH 5.0 and 37 °C [3], 50 RNase A activity units are equivalent to 1 Kunitz unit [4].

Product details